PRODUCTS

-

PU FOAM

-

Polyether Foam

COLOR & ADDITIVE

-

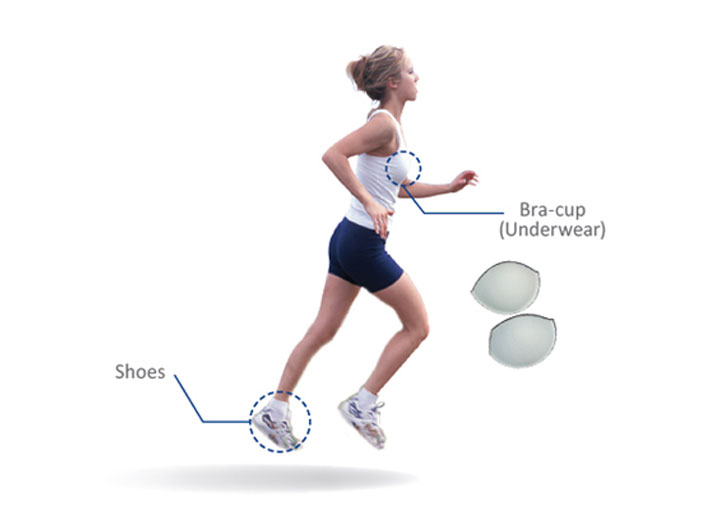

Shoes PU Foam

Unit : Grey Scale (AATTC / ISO 105)

Product UV Hydrolysis (water) Brand Standard RSL SUV-900 4.0 ↑ X Nike O SUV-5270 4.0 3.5 Adidas O

-

Test Condition

Unit : Grey Scale (AATTC / ISO 105)

SHOES Nike Spec. QUV 340 Lamp, 45℃ x 24hrs Adidas Spec. QUV : Suntest XLS+, 550 watt, 70℃ x 2hrs

Hydrolysis : 70℃ x 95%(Humidity) x 7dyasMizuno Spec. QUV : Suntest XLS+, 70℃ x 2hrs

Nox(Burn test) 24hrs per cycle

-

Bra-cup PU Foam

Unit : Grey Scale (AATTC / ISO 105)

Product Color Consistency (Grey Scale) 1 2 3 4 5 6 7 Heat Resistance In-Door(1 mth) QUV Phenolic Burnt Gas (Nox) Hydrolysis Hydrolysis+1press 1 press 2 press SUV-615 4.5 3.5 4.0 3.0 4.0 2.5~3.0 3.5 1.5 SUV-710 4.5 4.0 4.0 3.0 3.5 1.5~2.0 4.5 3.5 SUV-611N 4.5 3.5 4.0 3.0 4.0 3.0~4.0 3.5 1.5

-

Bra-cup PU Foam

Unit : Gray Scale (AATTC / ISO 105)

Product Color Consistency (Grey Scale) 1 2 3 4 5 Heat Resistance In-Door(1 mth) QUV Phenolic Burnt Gas (Nox) 1 press 2 press SUV-615 4.5 3.5 4.0 3.0 4.0 2.5~3.0 SUV-710 4.5 4.0 4.0 3.0 3.5 1.5~2.0 SUV-611N 4.5 3.5 4.0 3.0 4.0 3.0~4.0

-

Product Color Consitency (Grey Scale) 6 7 Hydrolysis Hydrolysis+1press SUV-615 3.5 1.5 SUV-710 4.5 3.5 SUV-611N 3.5 1.5

-

Super Whitening Agent

Dosage : 0.5 to 2.0 php

Product Color Viscosity (cps, 25℃) Appearance SUV-105 Violet 9,000 ↓ Paste SUV-106 Blue 9,000 ↓ Paste

92, Muha-Ro, 110Beon-Gil, Namyang-Eup, Hwaseong City, Gyeonggi-Do, Korea

- TEL 82-31-356-2397

- FAX 82-31-356-2399

- EMAIL sdkorea@sd-korea.com

COPYRIGHT(C)SD KOREA 2021. ALL RIGHTS RESERVED.